Since 1974

Use the system backed by decades of results.

We provide a long-lasting, low-impact solution for damaged foundations. Our independently owned-and-operated dealers deliver field-proven results.

Since 1974

We provide a long-lasting, low-impact solution for damaged foundations. Our independently owned-and-operated dealers deliver field-proven results.

With a 50-year track record, we pioneered the remedial steel pier repair market.

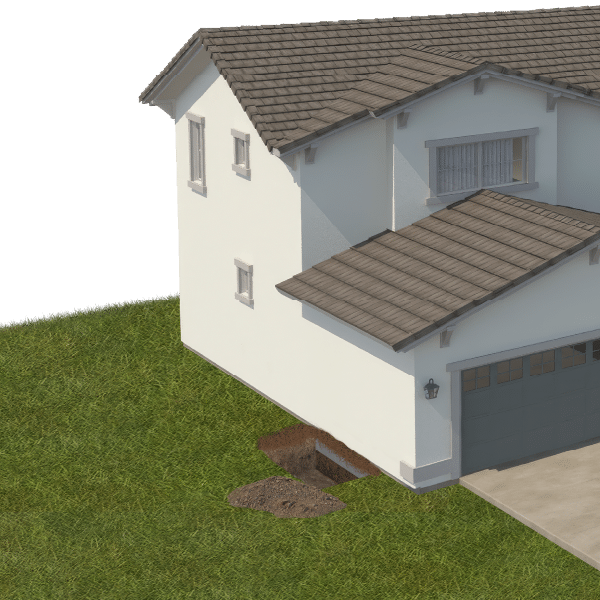

Our system requires minimal excavation, using the same tools from start to finish.

We source American-made materials to ensure precise and accurate repairs.

Our system bypasses problem soil to drive tubing into bedrock or equivalent strata.

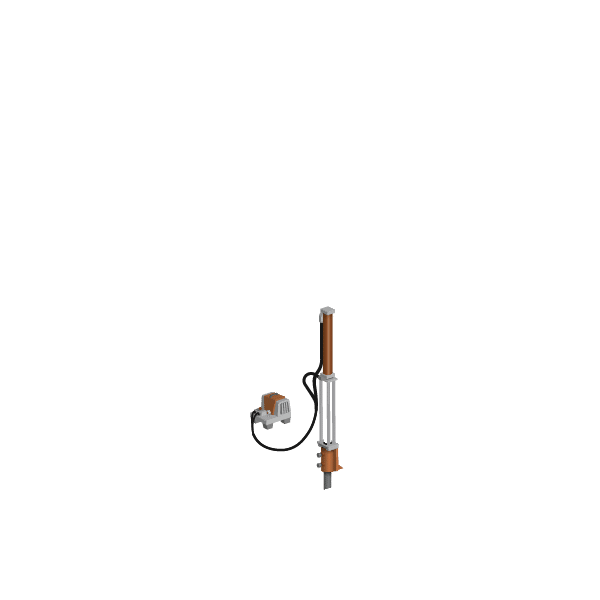

Made in the United States from high-yield ASTM A513 steel tubing.

Made in the United States from high-yield ASTM A513 steel tubing.

Doesn’t reach bedrock or load-bearing strata

Continues to settle in soft soil or clay

Requires frequent adjustments

Service contracts are costly

Doesn’t always reach bedrock or load-bearing strata

Requires additional labor

Aesthetic repairs are delayed while concrete hardens and grout is applied

Designed to hold things down, not up

Blade is often positioned in problem soil

May require troublesome and costly adjustments

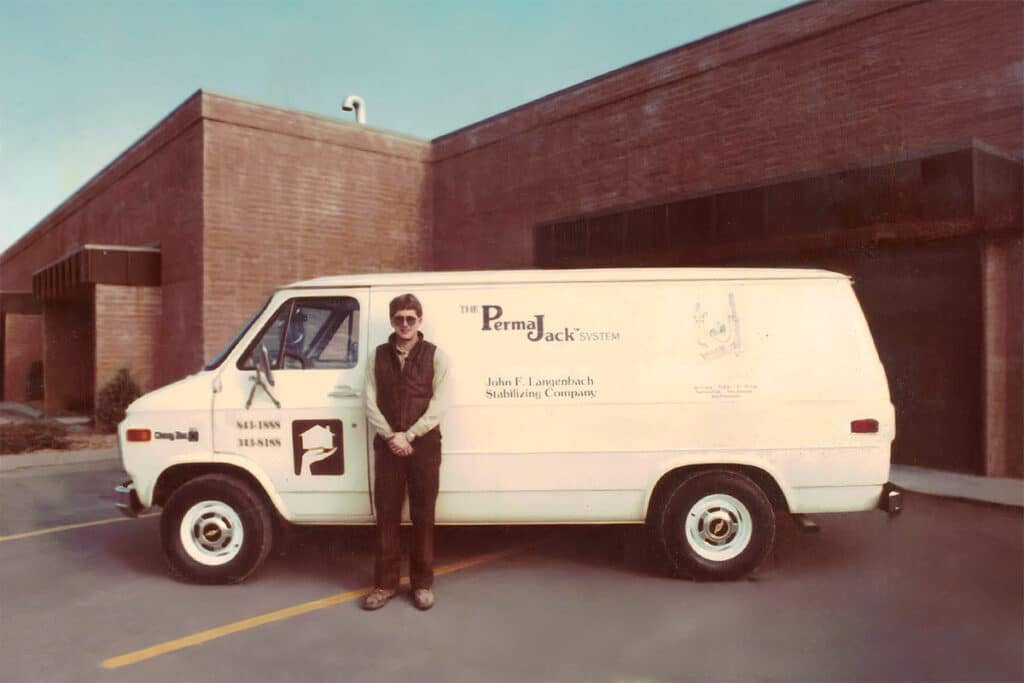

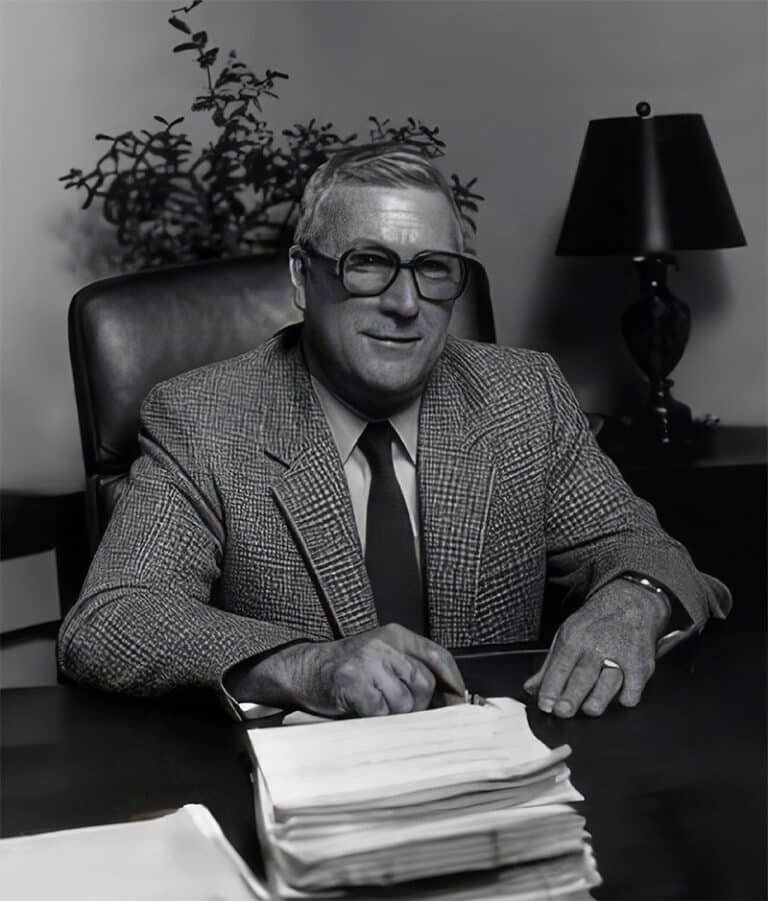

The Perma Jack® Story

After watching his neighbor’s ineffective and expensive foundation repair, George Langenbach set off to develop a better solution. In 1974, he revolutionized the industry with the Perma Jack® system which works like a bumper jack for foundations.

After franchising the system, George expanded to dealers across the country. Today, his son, John, continues this legacy.

Provide timely repairs by identifying the early indicators of a foundation problem.

Read This Post

The Perma Jack® system is a reliable and efficient solution for damaged foundations.

Read This Post

We use cookies to provide features and learn about visitors.